Function

With the automation of the Clayton control valve, you enter a new generation of monitoring and controlling your water supply.

With our products from the e-Line series you are able to realize almost any control task directly at the valve.

The components are perfectly adapted to the peculiarities and special behavior of the water.

The e-Line components are easily integrated into your control system, your control system builder only has to supply the control signals.

The control task is performed by the “e-Line”.

If you do not yet use a control system, you can use our products to set up individual or smaller control loops at low cost.

For fully programmable monitoring and control of pressure, flow, level and valve position.

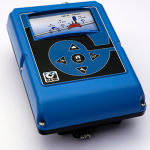

With the D22, many valve functions can be automated, even without existing control. Since the automatic control of the functions takes place at the valve on site, the electronic valve controller can also be used to simplify an overall control system.

- Power supply: from 12 – 24 V DC

- Display: TFT LCD Colors 4,3″

- Inputs: 6x analog 4-20 mA

- Connections: 6x digital (potential-free contact)

- Outputs:

x Analog 4-20 mA

2x solenoid valve

2x relay 6 A - Communication:

Connection: GPRS Modem Quad band

Ethernet RJ-45 / RS-232 / RS-485

Protocols: ModbusTCP / Modbust RTU / VNC - Functions:

4x PID Controller

4x control curves - Log Memory

- Protection class IP 68

- Pre-programmed standard applications, so-called ValvApps®, are already stored on the device, further ones can be programmed individually

- Material made of PC / ABS plastic, UV resistant

- Silicone sealed polycarbonate display

- Anodized aluminum mounting bracket

Manfred Wagner

- Head of control valves

Thomas Neuhold

- Sales control valves

Subject to changes