Hydrant service – safe and economical!

The aim of the annual control maintenance is to check the functionality of every hydrant and to document it for later evidence purposes.

Small repairs, which are carried out within the framework of the maintenance flat rate, guarantee the maintenance of the value of the hydrant network.

Safety

Hydrants that do not work in an emergency delay fire department operations and can result in claims for damages. We take responsibility for the proper maintenance of the hydrant network.

Economics

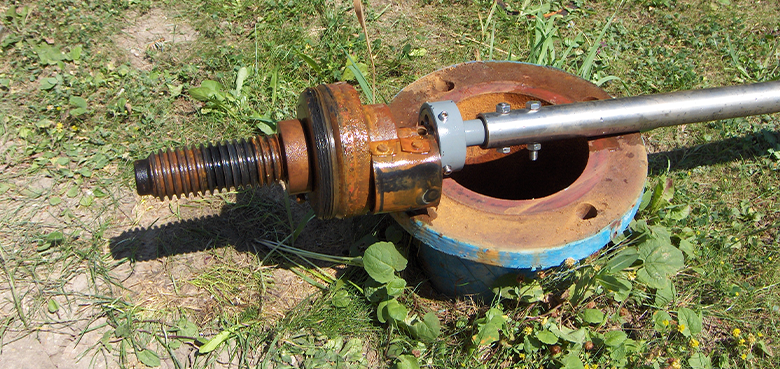

The biggest problem is defective main shut-offs, which cause high water losses and consequential damage. Damaged main barriers are tracked down using an electronic leak detection device.

Damage prevention

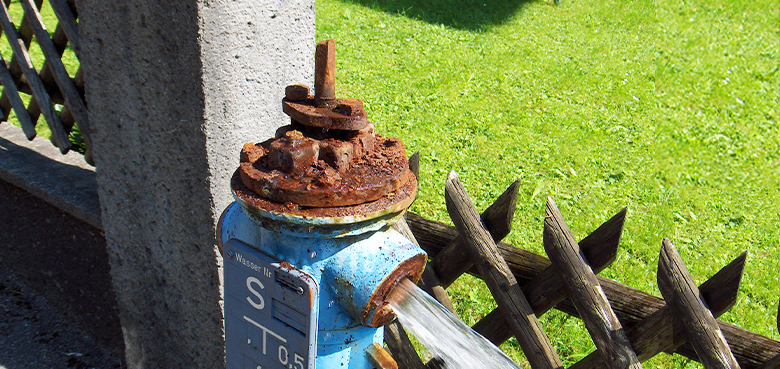

Permanently leaking hydrants cause enormous damage through leakage losses, setting of the level and accelerated corrosion of the fittings and pipes.